He field maintenanceIt is essential to ensure that a company’s equipment and machinery continue to function optimally.operational failurescan be expensive, not only in terms ofrepairs and downtime, but also inloss of production and damage to reputation. The implementation of effective strategiespreventive maintenance and predictivein the field is key to avoiding these problems and ensuring operational efficiency.

In this article, we will explore how thefield maintenancecontributes to theprevention of operational failuresand how thetechnological solutionscan improve this process for businesses.

Why is Field Maintenance Important?

He field maintenancerefers to theinspection, repair and adjustmentof equipment and systems that are located at the site of operation, outside of the central facilities or factories. This type of maintenance is crucial to preventoperational failureswhich can cause unforeseen stops in production lines,interruptionsin logistics ordamage to machinery.

He preventive maintenanceIt is based on actions programmed tocheck, clean, or adjustequipment before it fails. This helps identify and fix small problems before they become major failures.predictive maintenance, on the other hand, uses data andsensorsto predict when equipment might fail, allowing for more accurate and less costly repairs.

8000T Slide Label

Label Material Pressiza 13 Fluorecent paper

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 23 Silver Paper

Home 5/5 Details Related industries Technical sheet Quote...

How Field Maintenance Helps Prevent Operational Failures

1. Reduction of Unplanned Downtime

Regular maintenance of equipment and systems helps preventunplanned stopsthat can seriously affect production. Theconstant inspectionand theearly fault detectionallow companies to intervene before problems become emergencies, minimizing the impact on daily operations.

2. Increased Equipment Lifespan

He proactive maintenanceIn the field, this ensures that the equipment is in its best working order, which prolongs its useful life and improves its performance. Preventive interventions, such aschange of partsthecalibration settings, can prevent premature wear and help equipment run more efficiently for a longer period.

3. Better Asset Management

He field maintenanceallows better control of theindustrial assetsBy keeping detailed records of repairs, inspections and replacements performed on each piece of equipment, companies can optimizemanagement of your assets. This ensures that themaintenance planand that available resources are maximized.

4. Optimization of Resources and Costs

Proper field maintenance not only helps prevent failures, but also contributes to theresource optimization. Useadvanced technologiesmonitoring and diagnostics can reduce the need forreplacement of expensive equipmentand ensure that repairs are carried out only when necessary, resulting in acost savingssignificant.

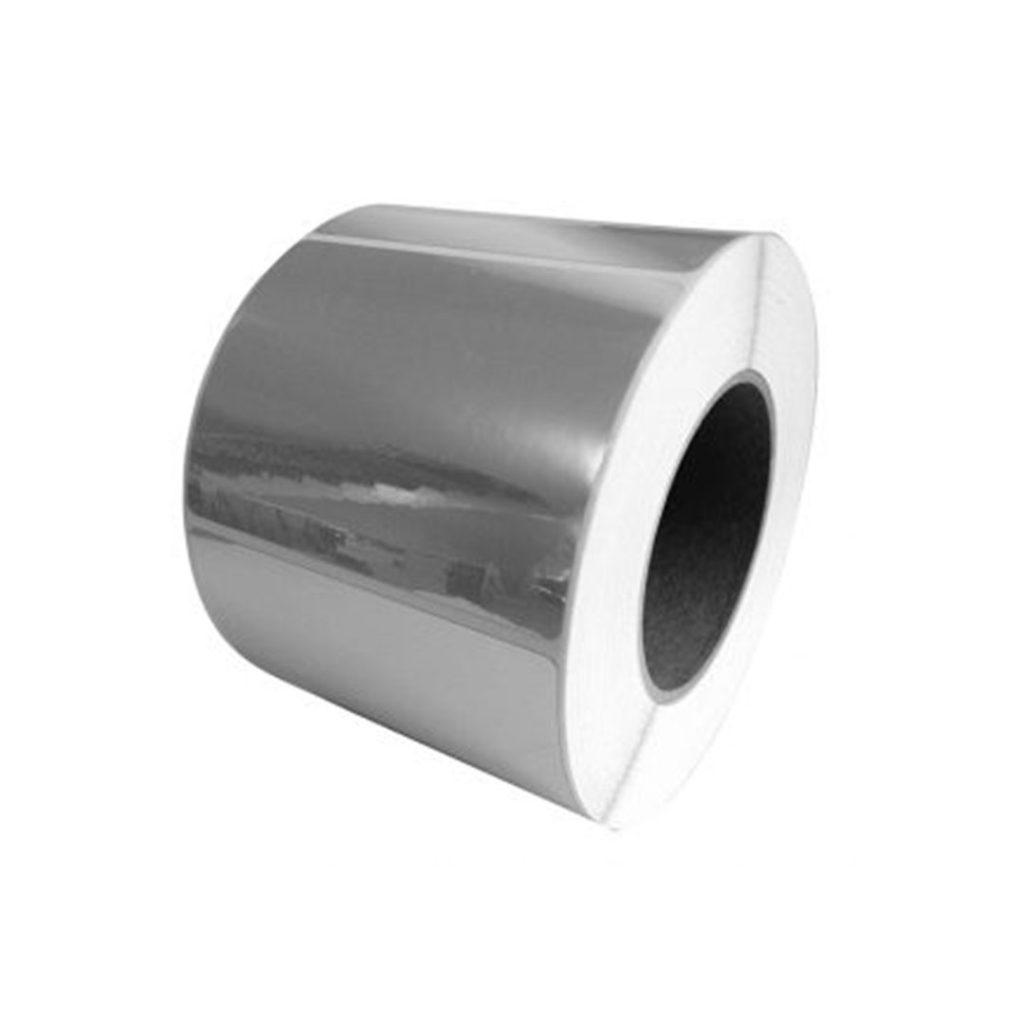

Impresora especializada FX3

Impresora de trasferencia térmica Pressiza PA-2408T

Impresora de tarjetas ZXP Series 7 RFID

Impresora/codificador industrial con RFID ZT231

Impresora RFID Series ZT400

Impresoras industriales RFID Series ZT400

Technological Solutions for Field Maintenance

The advanced technologiesare transforming thefield maintenance, improving their efficiency and effectiveness. Some of the key technologies include:

1. IoT Sensors and Real-Time Monitoring

The use ofIoT sensors(Internet of Things) allows monitoring the status of equipment in real time, which providescritical informationabout their operation. These sensors can detect any performance anomalies and alert technicians to take action before a major failure occurs.

2. Maintenance Management Software

He specialized software in maintenance managementIt helps to schedule and track preventive and predictive maintenance tasks. It also allows you to record all the activities performed, which facilitates future planning andlife cycle optimizationof the teams.

3. Augmented Reality (AR) Solutions

The augmented realityis being integrated into field maintenance, providing technicians with visual guides and remote assistance during repairs. Thisreduces errorsand improves the speed of interventions, especially in complex equipment.

4. Drones and Robots for Inspection

The use ofdrones and autonomous robotsFacilitates inspections in difficult-to-access or hazardous areas, improving safety and reducing field maintenance time.

How RSI Can Help with Field Maintenance

In RSI Mexico, we have solutionsadvanced technologiesto optimize thefield maintenanceand reduce operational failures. Our platformsasset Management and predictive maintenancecan help you monitor the status of your equipment in real time, plan preventive interventions and improve theoperational efficiency.

In addition, we offerrugged deviceswhich allow maintenance tasks to be carried out under difficult conditions, ensuring the continuity of operations without interruptions.

Our technicians are certified by:

Conclusion

He field maintenanceIt is essential to avoidoperational failuresand ensure the efficiency of industrial operations. By integrating advanced technologies such asIoT sensors, maintenance management software and predictive maintenance, companies can optimize their resources, reduce costs, and extend the life of their equipment. With the right solutions, you can keep your machinery inoptimal stateand improve your company’s productivity.

If you want to improve your processesfield maintenanceand reduce the risks of operational failures,RSI Mexicois here to help you with our specialized solutions.

What are your technical needs?

Andrés Alcantara

Especialista en Marketing digital