The safety in manufacturingIt is a fundamental aspect to guarantee a safe work environment, protect company assets, and comply with labor and safety regulations. One of the most important pillars of safety in an industrial environment is theaccess control. This system not only ensures that the right people have access to restricted areas, but also protects theconfidential information, the assetsand theintellectual propertyof the company.

In this article, we will explore how aaccess controlefficient improves thesecurityIn manufacturing, it protects company resources and ensures compliance with labor and industrial safety regulations.

Why is Access Control Important in Manufacturing?

He access controlIn manufacturing, it has a direct impact on several aspects of a company’s operations. Below, we detail some of the most important reasons why you should consider investing in a proper manufacturing system.industrial safety:

1. Protection of Assets and Resources

In a manufacturing plant, theassets, such as machinery, equipment and valuable materials, can be targets for theft or vandalism. A security systemaccess controlallows you to restrict entry to authorized personnel only, thus protecting your most important resources. In addition, these systems record theentrances and exits, providing a reliable trail in case of any incident.

2. Compliance with Safety Regulations

The labor regulationsand ofindustrial safetyrequire companies to maintain a safe working environment, especially in risk areas such aswarehousestheproduction areas. Implement a system ofaccess controlhelps ensure that only appropriate personnel enter hazardous areas, reducing the likelihood of accidents and ensuring compliance with regulations.

3. Reduction of Occupational Risks

In manufacturing plants, workplace accidents can have serious consequences.access controlis a key tool in preventing untrained or unauthorized persons from entering dangerous areas. Restricting access to certain areas can also minimizeoccupational hazards, protecting employees from potential accidents.

4. Access Monitoring and Auditing

He access controlnot only regulates the entry and exit of people, but also facilitates themonitoringand theauditof movements within the plant. Advanced systems can record information about who accessed which areas and at what time, facilitating follow-up in the event of incidents or security audits.

5. Improving Productivity and Personnel Management

By automating access control, businesses can reduce the time spent on manual monitoring and security controls. Employees can access their work areas quickly and efficiently, improving productivity.productivitygeneral. In addition, this system can be integrated with the platforms ofpersonnel management, facilitating attendance control and optimizing work shifts.

8000T Slide Label

Label Material Pressiza 13 Fluorecent paper

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 23 Silver Paper

Home 5/5 Details Related industries Technical sheet Quote...

Types of Access Control Systems in Manufacturing

There are different types of systemsaccess controlthat can be adapted to the specific needs of a manufacturing plant. Below are some of the most common options:

1. Access Control with RFID Cards

The RFID cardsare a popular choice for access control in manufacturing. These cards allow employees to enter restricted areas simply by waving them against a reader, providing quick, contactless access. Additionally,RFID cardscan be integrated with systemsattendance tracking and personnel management, offering comprehensive control.

2. Biometric Systems

The biometric systems, like those offingerprintthefacial recognition, are increasingly used in industrial environments due to their high level of security. These systems ensure that only authorized persons can access critical areas. They also offer astricter controlthan traditional cards, since the biometrics are unique to each individual.

3. Barcodes and QR

Systems based onbarcodestheQR codesThey are also used in access control. These systems are a more economical and efficient option for controlling personnel access in less sensitive areas. Employees can scan a code to enter a specific area, facilitating the entry control process.

4. Mobile App-Based Access Control

With the advancement of technology,mobile devicesThey have become an effective tool for access control. Mobile apps can be used to send electronic access credentials, providing a convenient and accessible option for staff. This type of system is especially useful for companies with mobile or temporary staff.

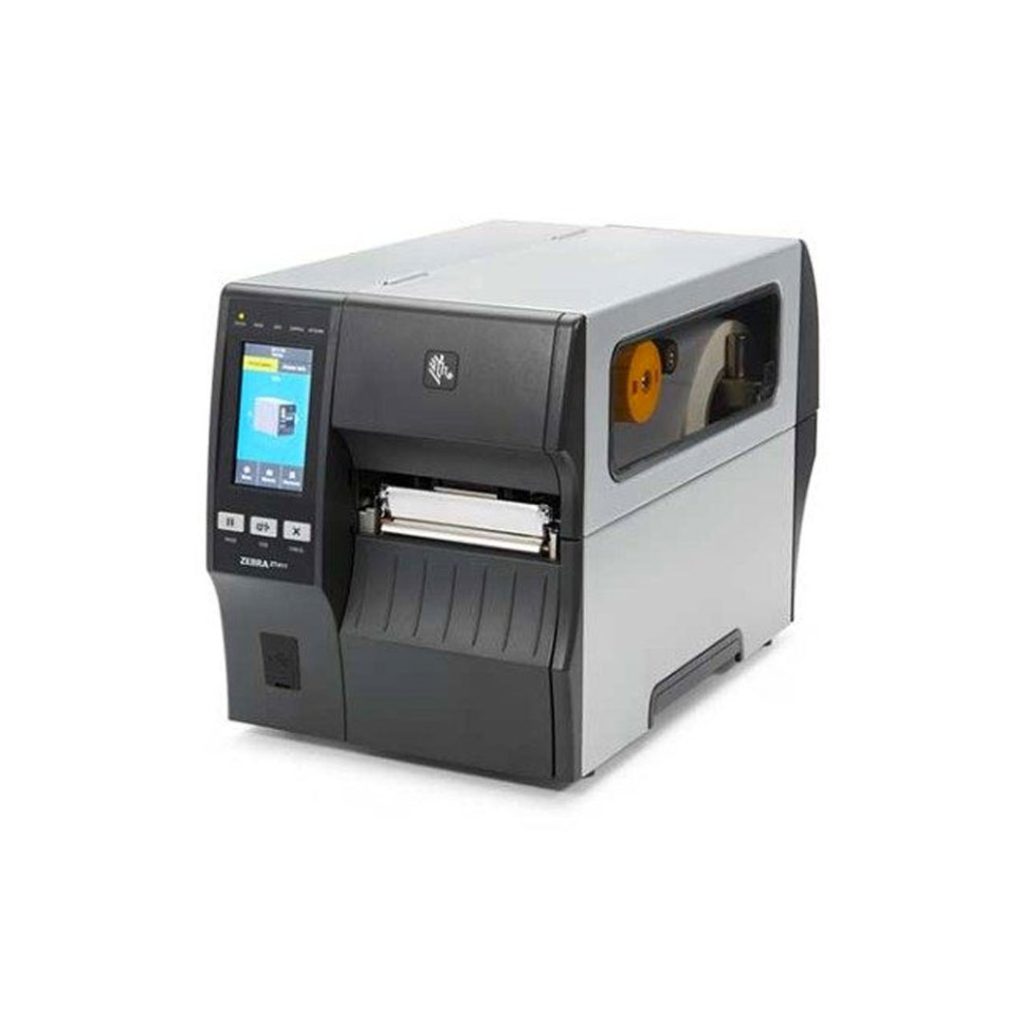

Impresora especializada FX3

Impresora de trasferencia térmica Pressiza PA-2408T

Impresora de tarjetas ZXP Series 7 RFID

Impresora/codificador industrial con RFID ZT231

Impresora RFID Series ZT400

Impresoras industriales RFID Series ZT400

How Can RSI Help with Manufacturing Safety?

In RSI Mexico, we offer complete solutions for theaccess controlthat integrate seamlessly with the systems ofsecurity management and personnel managementof your company. Our platforms useadvanced technologieshowRFID, biometrics and QR codes, guaranteeing asafe and efficient accessto restricted areas.

With our solutionsaccess control, you can protect yourassets, ensure compliance withsafety regulationsand optimize theproductivityof your team. Plus, our solutions are scalable and customizable, adapting to your company’s specific needs.

Conclusion

He access controlis essential to maintaining a safe and secure work environment in manufacturing. Implementing efficient safety systems not only helps protect theassets, but also reduces theoccupational hazards, says thecompliance with regulationsand improves theproductivityof the company.

If you are looking to improve theindustrial safetyin your manufacturing plant,RSI Mexicohas the right solutions for you. Contact us to learn how our solutionsaccess controlcan help you protect your assets and optimize your operation.

What are your technical needs?

Andrés Alcantara

Especialista en Marketing digital