In the world ofwarehouse management, he picking inteligentehas become a key factor in improving efficiency and accuracy. ThepickingRefers to the process of selecting and picking products from inventory for shipping or distribution. However, the traditional process can be slow, costly, and error-prone, negatively impacting theoperational efficiencyand the costs.

The advanced technologyhas transformed traditional picking into a faster, more accurate, and more cost-effective process. Through automation and the use of digital tools, such assoftware de pickingand thesmart logistics solutions, companies can optimize their warehouse and significantly improve their operations.

What is Smart Picking and How Does It Optimize Your Warehouse?

He picking inteligenteIt is an approach based on thetechnologyto optimize the product picking process in the warehouse. By integrating advanced tools such asinventory management systems, mobile devices, smart terminals and robots, companies can reduce the time and errors associated with traditional picking.

1. Automation of the Picking Process

One of the highlights of thepicking inteligenteis theautomation. By usingrobots, automated systems and scanning technologies, picking is done more quickly and efficiently. This not only reduces picking time but also decreases the possibility of human error, improving accuracy and the quality of customer service.

2. Storage Space Optimization

He picking inteligenteIt also improves warehouse organization. By using advanced technologies to track product locations in real time, space usage is optimized, avoiding clutter and congestion in the storage area. This allows for high-demand products to be closer to picking areas, reducing travel time and increasing efficiency.

3. Integration with Inventory Management Systems

The solutions ofpicking inteligenteThey integrate easily with theinventory management systems(WMS), providing real-time data on product availability and inventory status. This helps make more informed decisions about replenishment, product distribution, and optimization of logistics operations, reducing operating costs and improving overall efficiency.

4. Improved Accuracy and Error Reduction

The systems ofpicking inteligenteallow agreater precisionin the process of collecting products. Through thescanning technology(asRFID and barcodes), product identification errors are minimized, ensuring that customers receive exactly what they ordered. This not only improves customer satisfaction but also reduces costs associated with returns and reshipments.

8000T Slide Label

Label Material Pressiza 13 Fluorecent paper

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 23 Silver Paper

Home 5/5 Details Related industries Technical sheet Quote...

How Can RSI Help with Smart Picking?

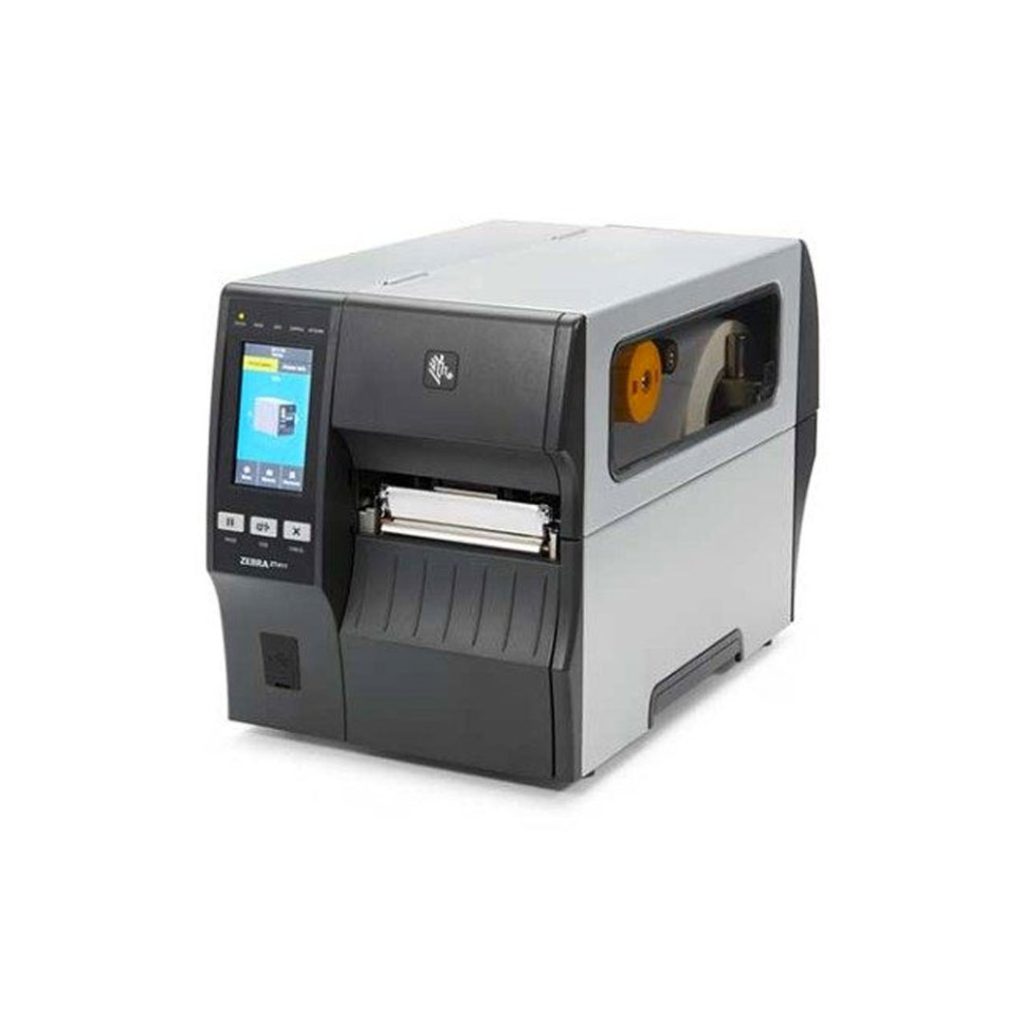

In RSI Mexico, we offer advanced solutions to optimize the process ofpickingin your warehouse. Ourtechnological platformsincludeinventory management systems(WMS) integrated with devicesmobile phones, smart terminals and RFID solutions, designed to make picking more efficient, faster and more precise.

Solutions We Offer:

- Mobile Terminals and Handheld Scanners: Ideal for rapid product collection, they allow for efficient and error-free picking.

- RFID systems: Integrated with picking solutions for more precise inventory management and significantly improved traceability.

- Inventory Management Software: To facilitate real-time control of available stock and optimization of picking routes within the warehouse.

- Automation and Robotics: Solutions for picking automation, improving product collection efficiency and reducing wait times.

With our solutions, you can transform your warehouse into an efficient distribution center, with abetter optimization of resources, reduction of operating costsand onegreater customer satisfaction.

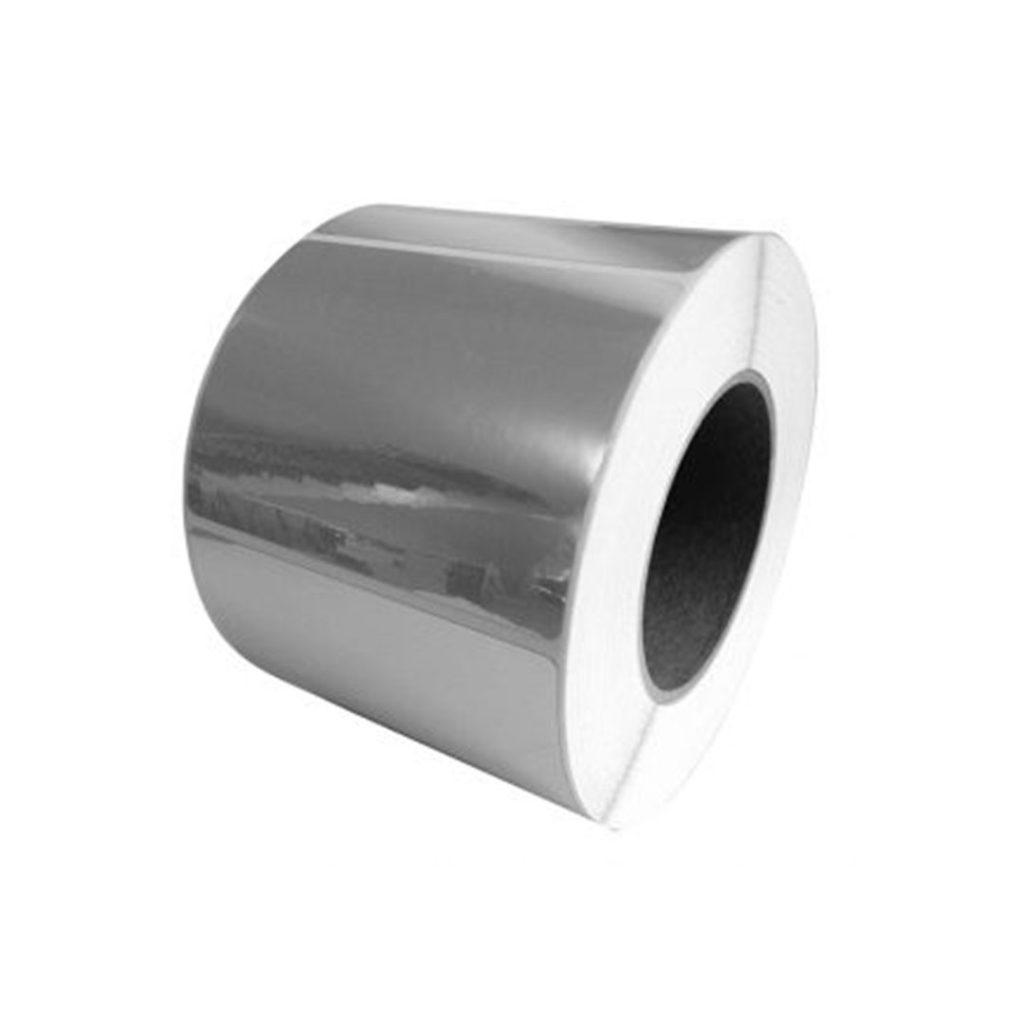

Impresora especializada FX3

Impresora de trasferencia térmica Pressiza PA-2408T

Impresora de tarjetas ZXP Series 7 RFID

Impresora/codificador industrial con RFID ZT231

Impresora RFID Series ZT400

Impresoras industriales RFID Series ZT400

Benefits of Smart Picking in Manufacturing and Distribution

He picking inteligenteoffers a wide range of benefits both in themanufacturing industryas in the sector ofdistribution:

1. Reduction of Operating Costs

Automation and optimization ofpickingThey reduce the time and resources required to fulfill each order. This reduces operational costs associated with inventory management, personnel management, and manual product picking.

2. Increased Productivity

By integratingadvanced technologyWith advanced technologies, such as mobile devices and automated systems, the time required to complete a picking process is significantly reduced. This increases the productivity of the team, allowing them to handle a larger volume of orders in less time.

3. Improved Customer Satisfaction

Picking accuracy improves thequality of customer service, reducing errors and returns. An efficient picking system ensures that the correct products are sent to the customer in a timely manner, which improves thecustomer experience.

Conclusion

He picking inteligenteIt is a key tool to optimize the process ofinventory management and storagein manufacturing and distribution. With the help of advanced technologies, such asrobots, scanning systems and inventory management software, companies can reduceoperating costs, increase theproductivityand improve theprecisionin their operations.

In RSI Mexico, we offer customized solutions foroptimize pickingin your warehouse. With our experience and technology, we can help you improve your company’s operational efficiency and achieve a competitive advantage in the market.

What are your technical needs?

Andrés Alcantara

Especialista en Marketing digital