Product labeling has undergone a remarkable evolution in recent years, adapting to the changing needs of industrial and consumer sectors. Synthetic materials, impact-resistant labels, and thermal labels have gained ground due to their ability to withstand extreme conditions and ensure the integrity of information on products that require robust labeling.

With technological advancements, smart labels and high-resistance materials are transforming the future of labeling—not only enabling product identification, but also tracking, control, and data analysis. In this article, we explore how these innovative materials are redefining labeling and how your company can benefit from these advanced solutions.

Synthetic Materials: The Evolution of Labeling

Synthetic materials are revolutionizing industrial labeling due to their durability, flexibility, and resistance. Unlike traditional materials like paper, synthetic plastics such as polypropylene and polyethylene offer greater resistance to water, extreme temperatures, and aggressive chemicals.

Advantages of Synthetic Materials

Greater Durability: Synthetic labels are more resistant to abrasion and tearing, making them ideal for products that face harsh conditions during transport and storage.

Moisture Resistance: Unlike paper labels, synthetic labels do not deteriorate when exposed to water, making them perfect for products stored in humid or frozen environments.

Design Flexibility: Synthetic materials allow for a wider range of designs, from flexible labels for small products to rigid labels for heavy industrial equipment.

8000T Slide Label

Label Material Pressiza 13 Fluorecent paper

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 23 Silver Paper

Home 5/5 Details Related industries Technical sheet Quote...

Impact Labels: Resisting Extreme Conditions

Impact labels are designed to withstand harsh usage and handling conditions. These materials are essential in industries where products are exposed to shocks, drops, or high-vibration conditions, such as automotive, electronics, and heavy logistics.

Characteristics of Impact Labels

Shock Resistance: Labels made from high-impact materials can withstand damage from falls or strong impacts without losing the readability of the information.

Adaptability: They can conform to irregular or hard-to-label surfaces, such as industrial equipment or heavy machinery.

Long-Term Durability: Thanks to their strength, impact labels maintain their integrity and functionality for years, even in difficult conditions.

Thermal Labels: Innovation for Extreme Temperatures

Thermal labels are essential for applications that require consistent performance under high or low temperatures. This type of labeling is especially important in industries such as food, pharmaceuticals, and cold chain logistics.

Benefits of Thermal Labels

Performance in Extreme Conditions: Thermal labels are designed to function reliably across a wide temperature range, from freezing conditions in cold storage to high temperatures in manufacturing processes.

Cold Chain Applications: They are ideal for products that must be kept under controlled temperature conditions, such as frozen foods and pharmaceuticals.

Long-Lasting Labeling: Thermal labels ensure that information remains legible and durable even in hostile environments, ensuring correct product identification throughout their lifecycle.

The Impact of Innovation in Labeling

Advancements in synthetic materials, impact labels, and thermal labels not only improve label durability but also optimize logistics and production processes. Smart labels also enable real-time data collection, facilitating product tracking and traceability throughout the supply chain.

How These Innovations Benefit Your Business

Improved Visibility and Tracking: Advanced labels allow continuous tracking of products throughout their lifecycle, improving operational efficiency and inventory control.

Error Reduction: The durability and resistance of new materials ensure that labels are not damaged or deteriorated, reducing errors associated with poor labeling or information loss.

Regulatory Compliance: In sectors such as food and pharmaceuticals, proper labeling is critical for compliance with safety and traceability regulations. Resistant labels ensure that information remains intact, even in extreme conditions.

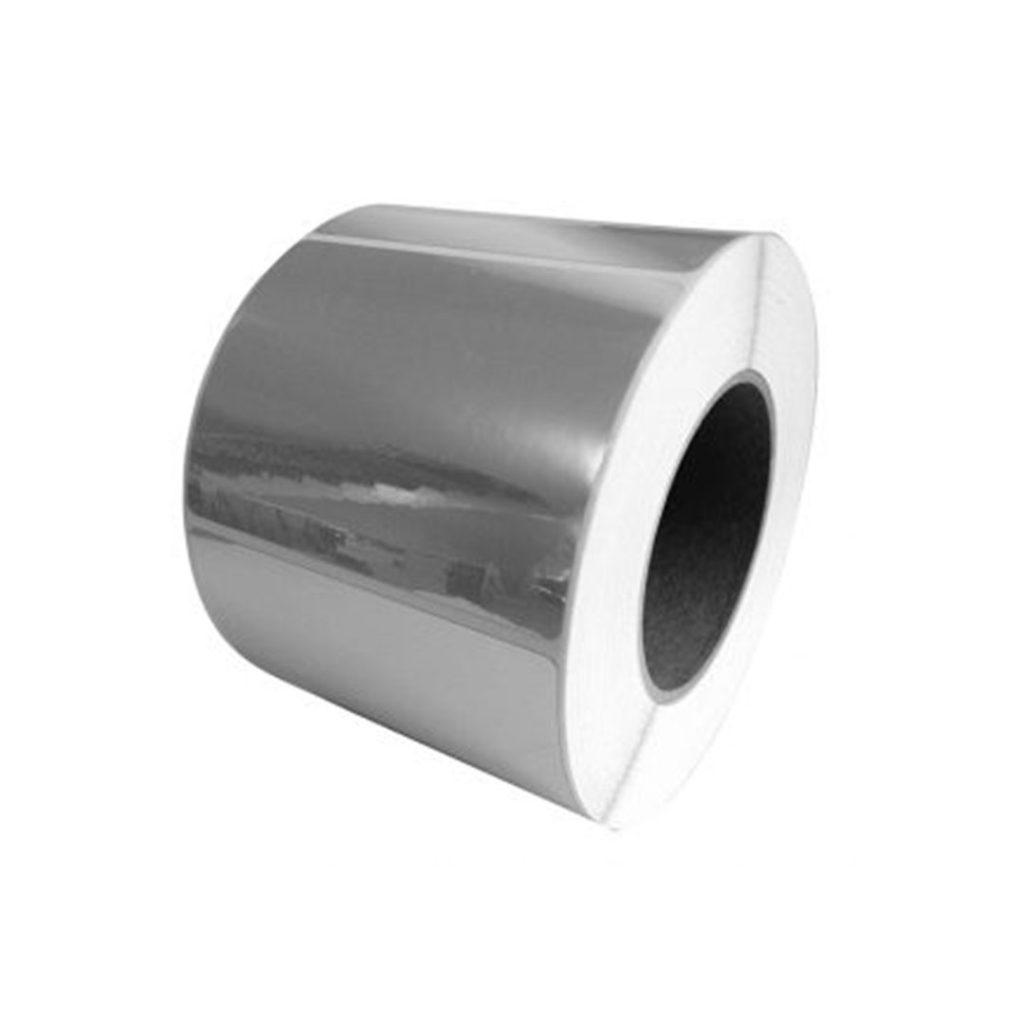

Impresora especializada FX3

Impresora de trasferencia térmica Pressiza PA-2408T

Impresora de tarjetas ZXP Series 7 RFID

Impresora/codificador industrial con RFID ZT231

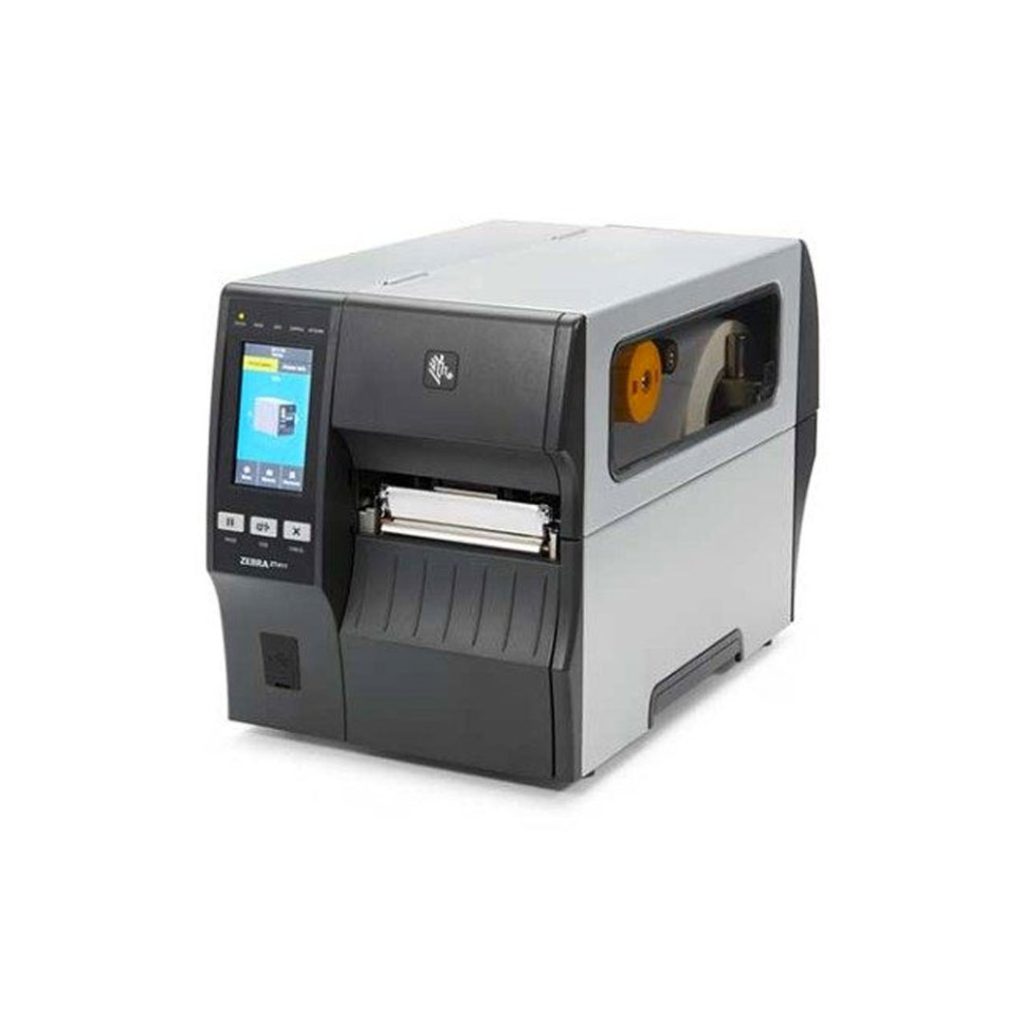

Impresora RFID Series ZT400

Impresoras industriales RFID Series ZT400

RSI: Advanced Labeling Solutions for Your Business

At RSI México, we offer a wide range of industrial labeling solutions, including synthetic materials, impact-resistant labels, and thermal labels. These solutions are designed to improve operational efficiency and ensure your products are labeled properly and can withstand the most demanding conditions.

Labels for Extreme Conditions: Resistant to moisture, impact, and extreme temperatures.

Custom Labels: Tailored to your business needs, ensuring every label meets your specific requirements.

Advanced Printing Systems: With Diagraph solutions that deliver high-quality, durable printing.

Conclusion

The future of labeling is clearly moving toward the use of innovative materials that improve durability, resistance, and adaptability. Synthetic materials, impact labels, and thermal labels represent the future of product identification in industrial sectors that require robust and reliable labeling.

If you’re looking for advanced labeling solutions, RSI México offers cutting-edge technology and high-quality materials that guarantee the performance of your products in any environment.

Contact us to learn how we can optimize your labeling process!

Impresora especializada FX3

Impresora de trasferencia térmica Pressiza PA-2408T

Impresora de tarjetas ZXP Series 7 RFID

Impresora/codificador industrial con RFID ZT231

Impresora RFID Series ZT400

Impresoras industriales RFID Series ZT400

¿Cuáles son tus necesidades técnicas?

Andrés Alcantara

Especialista en Marketing digital