The automation in manufacturinghas emerged as one of the most significant trends in modern industry. With the constant search forgreater efficiency to operational and cost reduction, companies are adopting advanced technologies to optimize their production processes. Sinceindustrial robots until automated quality control systems, automation allows companies to not only increase theproduction speed, but also improve accuracy and reduce human error.

The Industry 4.0has driven automation, but theIndustry 5.0will take this trend to new levels, with the integration ofartificial intelligence (IA), big data and machine learning systemsIn this context, companies that do not adopt these technologies risk being left behind. Below, we explore how automation is transforming manufacturing and how companies can leverage it to achievehigher levels of efficiency.

What Is Automation in Manufacturing?

The automation in manufacturinginvolves the use ofadvanced technologyto carry out production tasks that were previously performed manually. This includes the use ofindustrial robots, automated machines, digital control systems, and production management softwarethat work together to reduce human intervention, improve production speed, and increase product quality.

8000T Slide Label

Label Material Pressiza 13 Fluorecent paper

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 23 Silver Paper

Home 5/5 Details Related industries Technical sheet Quote...

1. Production Optimization

One of the main benefits of theautomation in manufacturingis theoptimization of production processesAutomated machines can work without interruptions, which increases productivity.operational efficiencyand allows companies to maintain a constant flow of production. In addition, automation reduces downtime and improves productivity.use of resources, which in turn reduces operating costs.

2. Improved Quality and Accuracy

The automationallows companies to maintain tighter control over their production processes. Machines and robots, when properly programmed, can perform tasks with aprecisionmuch larger than human operators. This not only improves thequalityof the final product, but also reduces the possibility of errors, which can result indefectsthewaste of materials.

3. Reduction of Operating Costs

While the initial investment inautomation technologymay be significant, the long-term benefits are indisputable.manufacturing automationreduces the need for human intervention in repetitive tasks, which decreaseslabor costs. In addition, improved efficiency and accuracy reduce thewaste of materials, which in turn contributes to a lower cost per unit produced.

How Is Automation Changing Manufacturing?

The progress in theautomationis completely reconfiguring traditional production models. New technologies, such ascollaborative robots (cobots), los machine vision systemsand thecloud-based production management platforms, are making factories smarter, more efficient and safer.

1. Collaborative Robots (Cobots)

The cobotsThey are robots designed to work alongside humans in the same work environment, complementing their skills without completely replacing them. These collaborative robots allow companies to maintain theflexibilityin their operations while increasing productivity.

2. Sensors and the Internet of Things (IoT)

He Internet of Things(IoT) has been fundamental to theautomation in manufacturing. Sensors installed in the machines allow data to be collected in real time, which facilitates theremote monitoringand predictive maintenance of equipment. This not only optimizes theperformanceof the machines, but also reduces unexpected downtime.

3. Production Management and Control Systems

The systems ofproduction managementThey allow for constant process monitoring and detailed control of operations. Thanks to automation, these systems can adjust workflow in real time, maximize resources, and maintain optimal production levels.

Benefits of Automation in Manufacturing

1. Greater Operational Efficiency

The automationallows companies to carry out their production processes in a more efficient mannerfast and efficientBy reducing downtime, eliminating inefficiencies, and optimizing resource utilization, companies can increase production without increasing operating costs.

2. Reduction of Human Errors

With theautomation, human intervention is limited to supervision and control. This helps toreduce human errorsthat can affect thequalityof the product, which improves operational reliability and reduces costs arising from rework or returns of defective products.

3. Increased Competitiveness

The automationallows companies to be more competitive by improving their ability tomeet deadlines and reduce costsAutomated companies can offer high-quality products at lower prices and with faster delivery times, giving them a significant advantage over competitors.

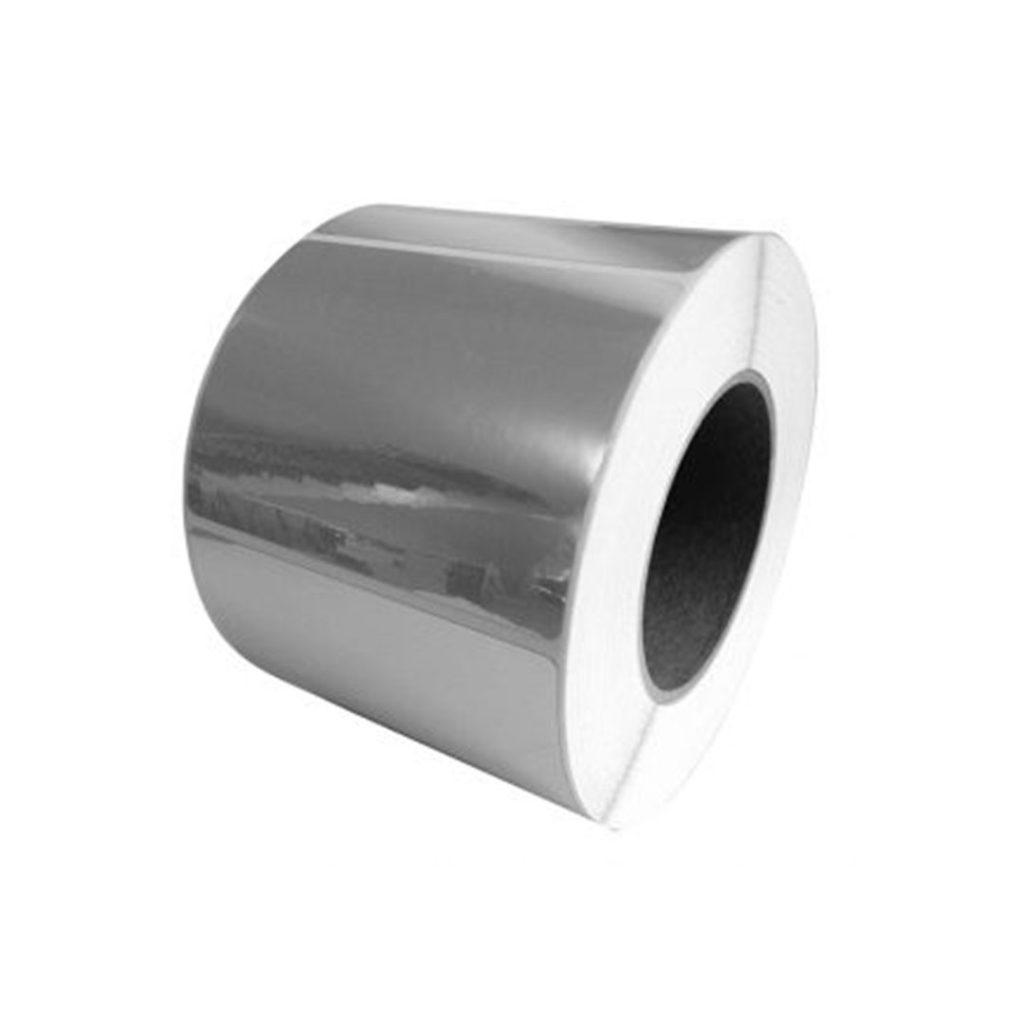

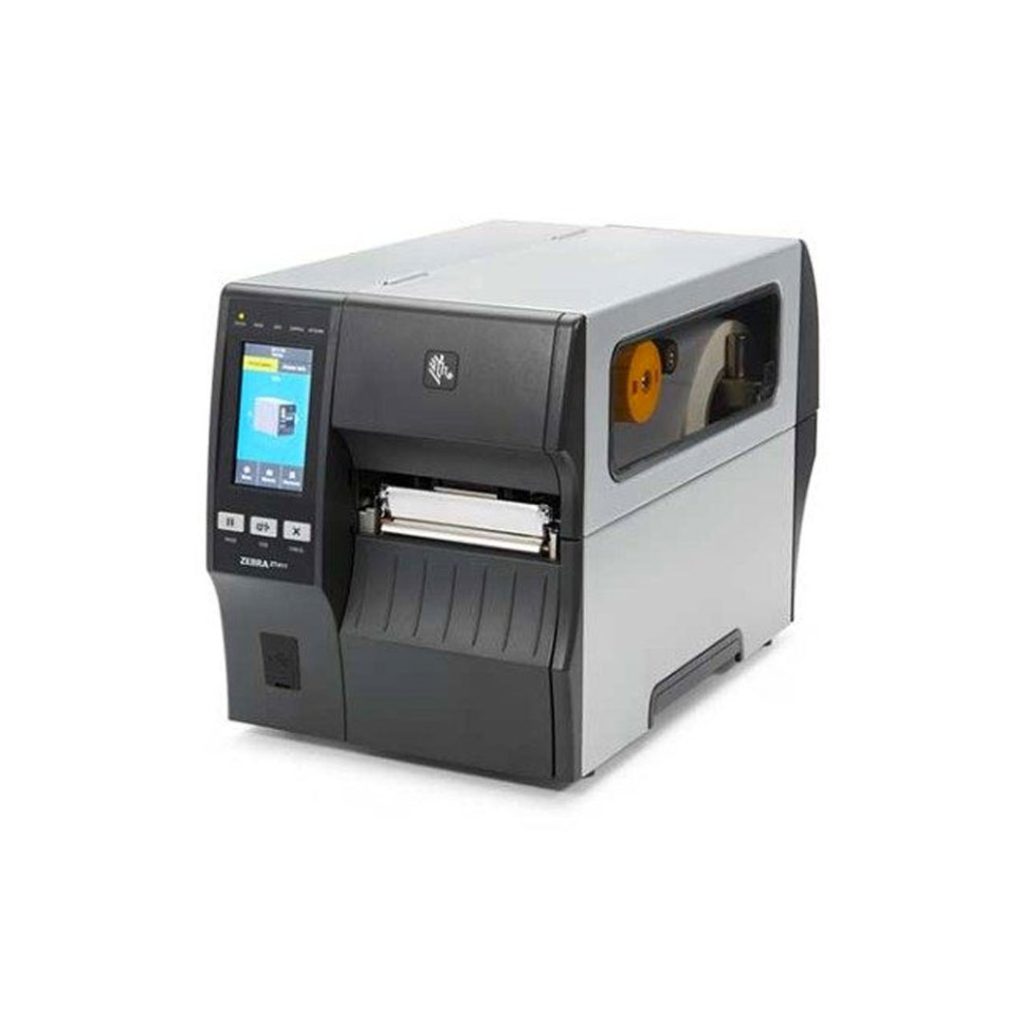

Impresora especializada FX3

Impresora de trasferencia térmica Pressiza PA-2408T

Impresora de tarjetas ZXP Series 7 RFID

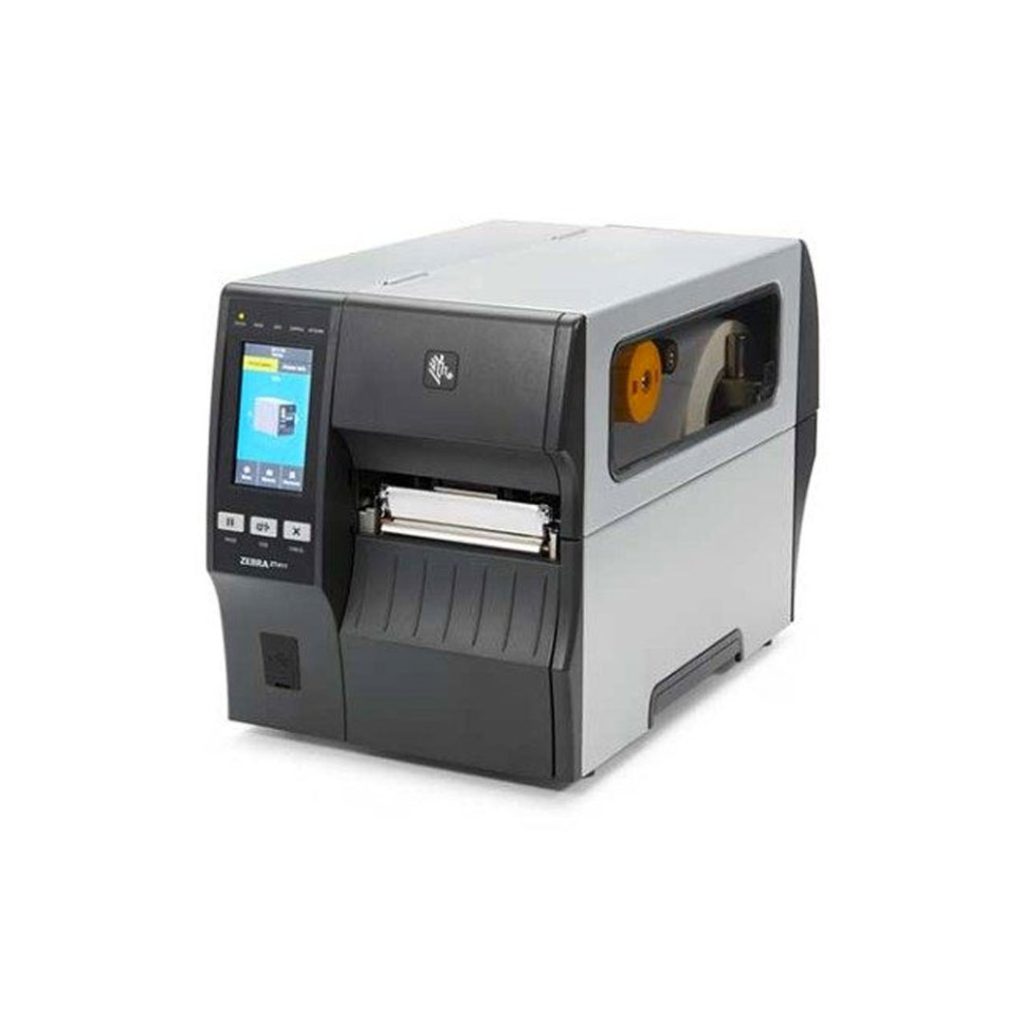

Impresora/codificador industrial con RFID ZT231

Impresora RFID Series ZT400

Impresoras industriales RFID Series ZT400

How RSI Can Help with Automation in Manufacturing

In RSI Mexico, we offer technological solutions that can help you carry out theautomationfrom your manufacturing to the next level. Frominventory management systems and process control platforms, until RFID solutionsFor traceability, we can help you optimize your production and improve the efficiency of your plant.

Solutions We Offer:

- Automation of Production Processes: We implement systems that integrate theautomationof repetitive tasks to improve efficiency and reduce labor costs.

- Real-Time Inventory Control: With our RFID solutions andinventory management systems, we optimize theresource managementand product availability.

- Predictive Maintenance: We useIoT sensorsto predict machinery failures and prevent unexpected downtime, improving overall plant efficiency.

- Management Software Integration: We offer you customized platforms forcontrol and superviseall aspects of your production process efficiently and in real time.

With our solutions, we can help youoptimize your manufacturing plant, improve theproduct qualityand reduce theoperating costs.

Conclusion

The automation in manufacturingis essential for companies seeking to remain competitive in an increasingly demanding environment. By integratingadvanced technology, asrobots, control systems and management software, companies can improve efficiency, reduce costs and optimize their production processes.

In RSI Mexico, we are ready to accompany you in thisjourney towards automationWith our customized solutions, we can help you take the next step in the evolution of your manufacturing plant.

Impresora especializada FX3

Impresora de trasferencia térmica Pressiza PA-2408T

Impresora de tarjetas ZXP Series 7 RFID

Impresora/codificador industrial con RFID ZT231

Impresora RFID Series ZT400

Impresoras industriales RFID Series ZT400

¿Cuáles son tus necesidades técnicas?

Andrés Alcantara

Especialista en Marketing digital